Popular Solutions

Our experiences with C&C have always been top notch. Your customer service is second to none and your turn-around/delivery times are always as stated with expediting when possible. It has been a pleasure working with you and your team at C&C as well, looking forward to many future projects together.

Brad Schoenberg, Admin., QA

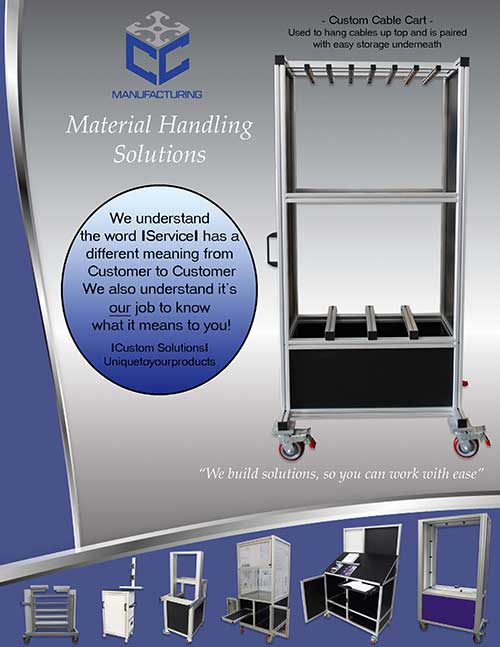

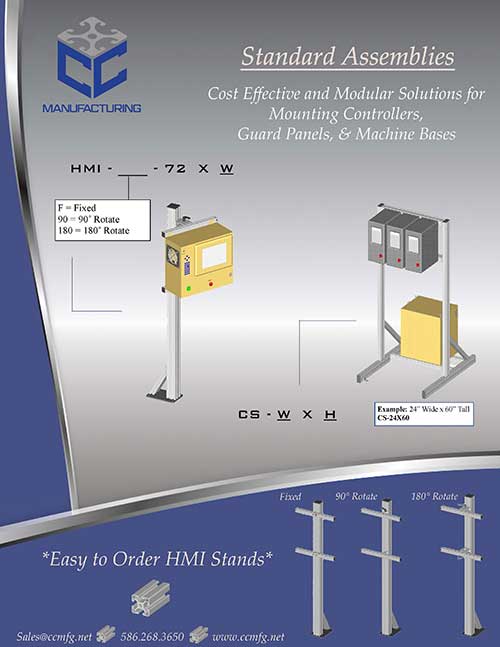

Custom Design Services

Our experts have worked with a number of designs and can help you create an innovative product that’s perfect for your needs.

Assembly Services

We’re a full service partner. After we solidify your designs, we can then complete the full assembly—quickly and cost-effectively.

Delivery Services

We guarantee your orders will get to you on time and safely. We take great care in designing, building and delivering all of our products.